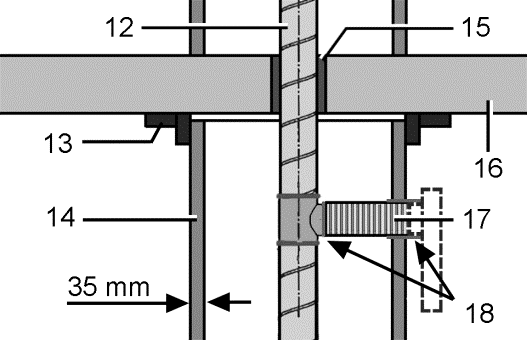

Preparations for wall installation (with fire protection)

12 | Main duct (steel folded spiral-seams duct) |

13 | Spigot |

14 | Shaft wall |

15 | Ceiling compound |

16 | Floor ceiling |

17 | Connection duct: Flexible aluminium duct AFR 80 |

18 | Sealing material, e.g. cold-shrink tape |

(Requirements in line with approval).

Damage to unit, malfunctioning in the event of corrosion damage from mortar.

Damage to unit, malfunctioning in the event of corrosion damage from mortar.

- Wrap ventilation ducts, connected to the unit, with a suitable adhesive tape to protect against corrosion inside the brickwork, e.g. using cold-shrink tape.

- Correctly attach main ventilation duct inside the shaft.

- Apply ceiling compound. To do this, encase the ceiling and pour in the material from above.

- Make a wall or shaft opening for the flexible aluminium duct.

Danger to life due to fire transmission in case of faulty ceiling compound.

Danger to life due to fire transmission in case of faulty ceiling compound.- It is essential that the remaining gap between the main duct and the wall or ceiling is completely sealed with non-flammable materials that are resistant to deformation. For example, use concrete or cement mortar.

- Connect the flexible aluminium duct to the main duct and seal for ventilation.

- Cut flexible aluminium duct to length, observe a maximum duct length of 2 m.

- Ensure a suitable, level substructure.

- Attach spigot made from shaft material F90 around the shaft.

- Continue with the safety test of the APB shut-off device: Safety instructions for installation of the fire protection shut-off device.

It is essential that requirements in line with approval are observed

It is essential that requirements in line with approval are observed