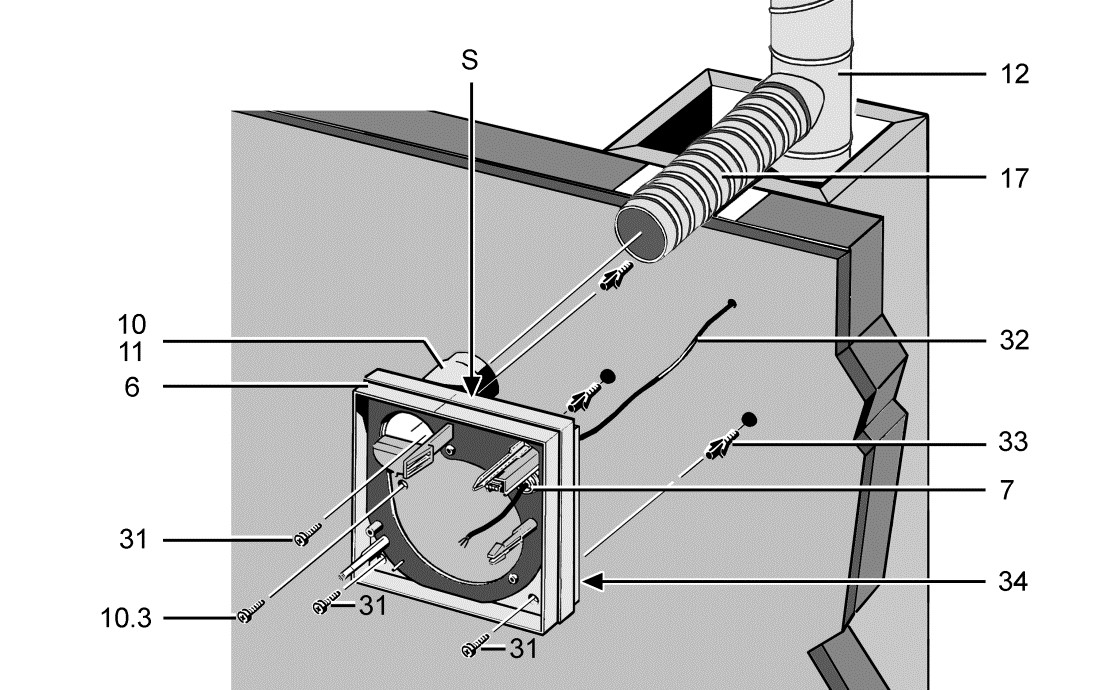

Wall installation, lower part of housing

6 | Lower part of housing |

7 | Cable grommet |

10 | Metal connection socket with ER-APB shut-off device |

10.3 | ER-APB: Fixing screw, to be provided by the customer |

11 | Plastic connection socket with ER-AP plastic backflow preventer |

12 | Main duct (steel folded spiral-seams duct) |

17 | Connection duct: AFR 80 flexible aluminium duct |

31 | Fixing screw (3 items, to be provided by the customer) |

32 | Power cable |

33 | Dowel (to be provided by the customer) |

34 | Housing seal |

S | Nominal opening for surface-mounted connection |

- Switch off mains fuse, secure against being accidentally switched back on and position a visible warning sign.

- Mark fixing holes on wall: 3x fixing holes for lower part of housing. For ER-APB, also 1x fixing hole for tab (ER-APB: Safety instructions for installation of the fire protection shut-off device) of metal exhaust socket. It is essential that the permissible installation positions are observed.

- Drill fixing holes and insert dowels. Suitable mounting material is to be provided by the customer.

- Check ease of movement of shut-off shutter/backflow preventer. When installed, the shut-off shutter/backflow preventer must close automatically.

- When the power cable is surface installed at position “S”, knock out the housing segment at the nominal opening and cut small recesses into the cross struts on the rear of the lower part of the housing to route the ducts.

Danger of short-circuits and damage to the unit. If the power cable is incorrectly fed or if the cable grommet is not fitted correctly, water may penetrate into the fan housing. The degree of protection cannot be guaranteed.

Danger of short-circuits and damage to the unit. If the power cable is incorrectly fed or if the cable grommet is not fitted correctly, water may penetrate into the fan housing. The degree of protection cannot be guaranteed.Pierce the cable grommet so that it tightly seals the power cable. Guide the surface-mounted or flush-mounted cables correctly into the intended cable grommet.

- Pierce a round opening in the cable grommet with a grommet puncher.

- Guide the power cable into the terminal compartment such that the cable grommet fits around the cable sheathing completely.

Fire may spread if connection duct is incorrectly installed.

Fire may spread if connection duct is incorrectly installed.- Only use permitted duct material

- Correctly attach connection duct to exhaust socket.

- Pull connection duct out of wall/shaft.

The noise level will increase if the housing seal is fitted incorrectly.

The noise level will increase if the housing seal is fitted incorrectly.- Ensure that the housing seal is correctly inserted into the lower part of the housing all the way round.

- Check/ensure that housing seal is fitted correctly all the way round.

- Slide connection duct up to stop above exhaust socket. Connection between connection duct and exhaust socket must be leak-tight, use cold-shrink tape for example.

Prescribed mounting material

| Steel screw | Steel dowel |

|---|---|---|

Masonry or concrete | ● | ● |

Panel building materials | ● |

|

- Use 3 screws to secure the bottom part of housing to the wall. For ER-APB, also screw down tab of connection socket with fixing screw. Suitable mounting material is to be provided by the customer. Again check ease of movement of shutter/backflow preventer. When installed, the shut-off shutter/backflow preventer must close automatically.

It is essential that the safety instructions provided in these instructions for the shut-off device or shutter are observed.

It is essential that the safety instructions provided in these instructions for the shut-off device or shutter are observed.