Retrofitting PTC heat register

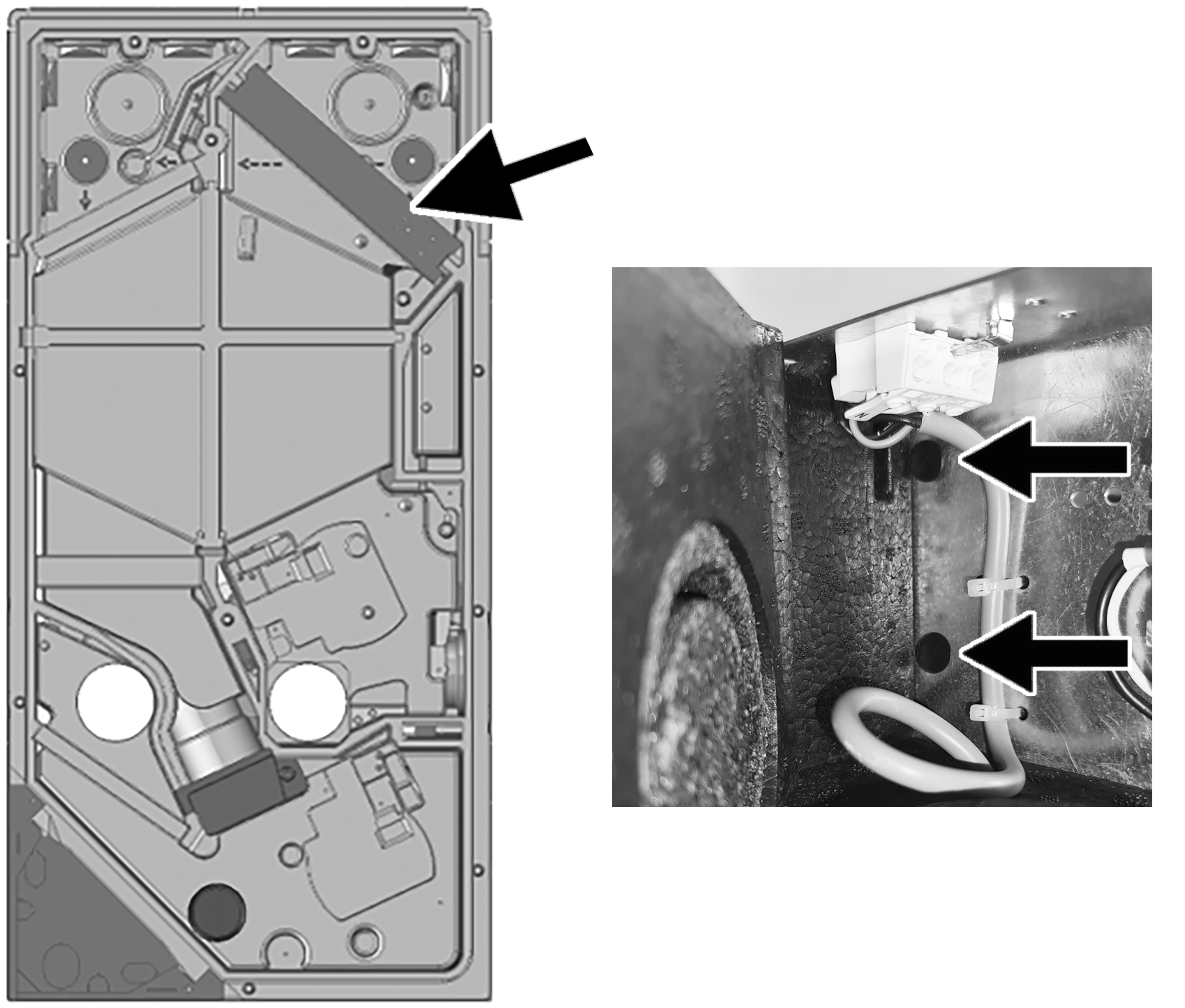

- Powerbox H: Remove WS 75 APA/UPA/UPGA cover. Powerbox S: Remove any cover that may be present.

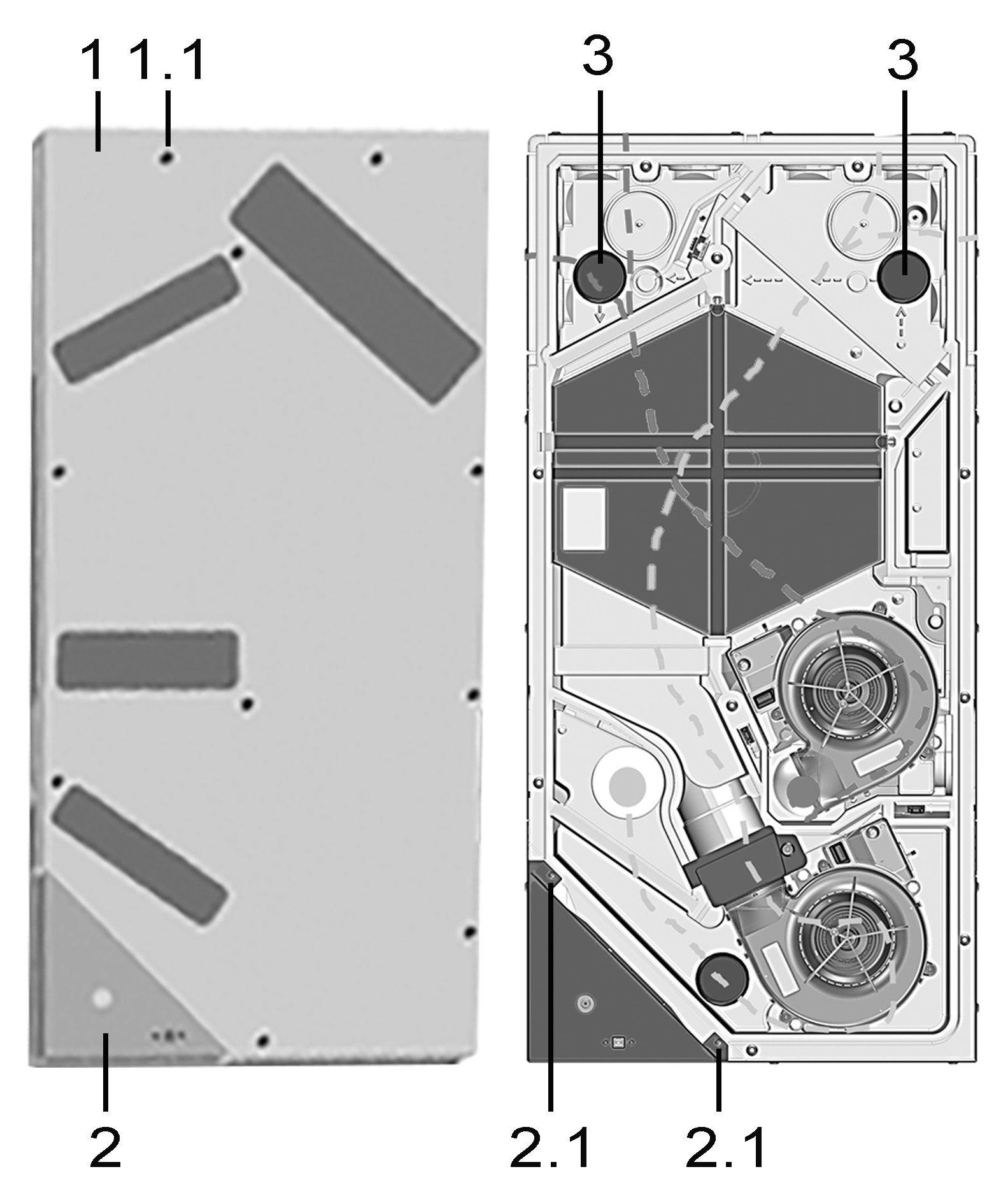

1

Housing cover

1.1

Screws for housing cover, 10 pieces

2

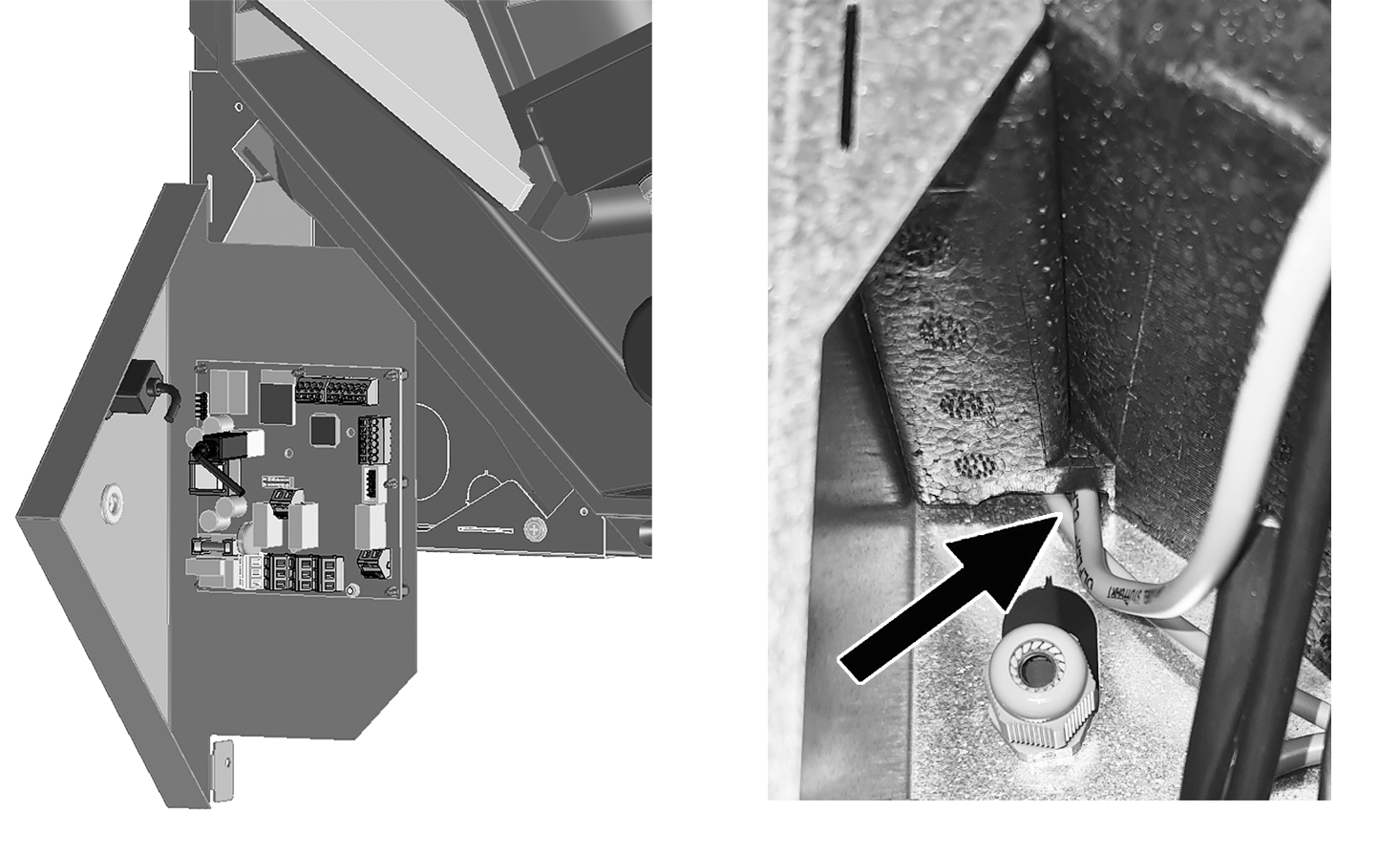

Electronics compartment with main circuit board A1

2.1

Fastening screws for electronics compartment

3

EPP sealing plugs

- Remove the cover of electronics compartment (2 screws).

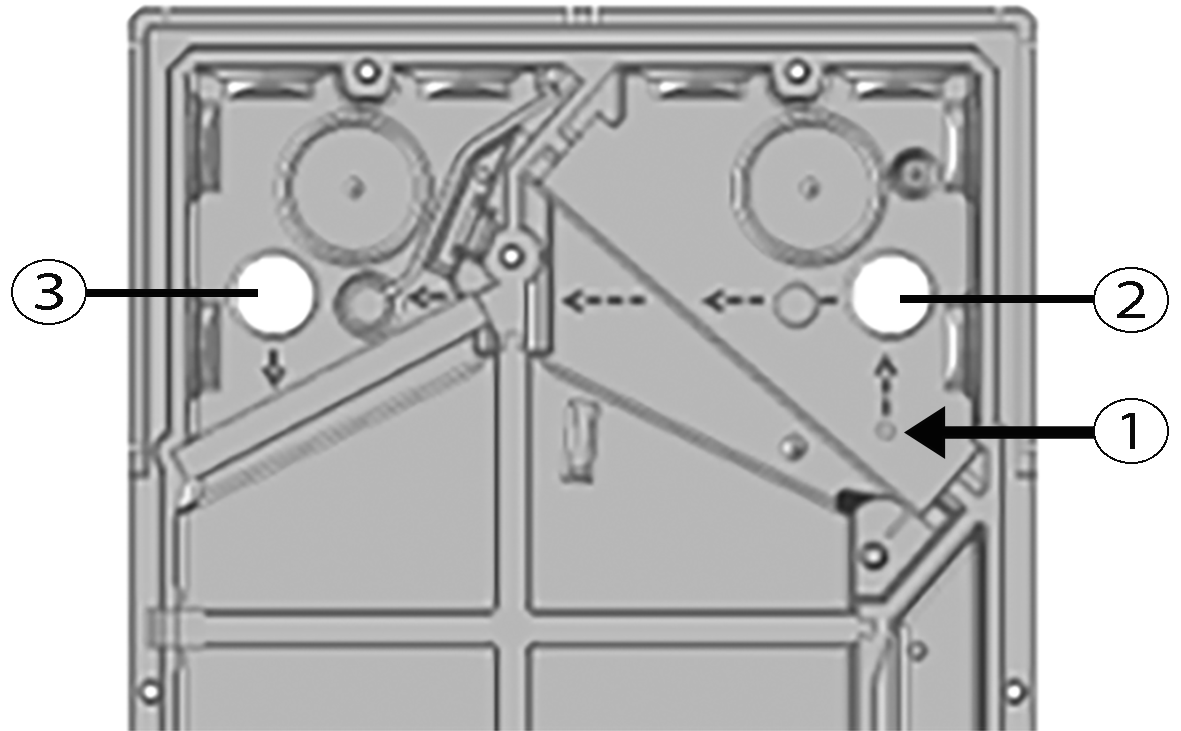

- Remove both of the upper EPP sealing plugs.

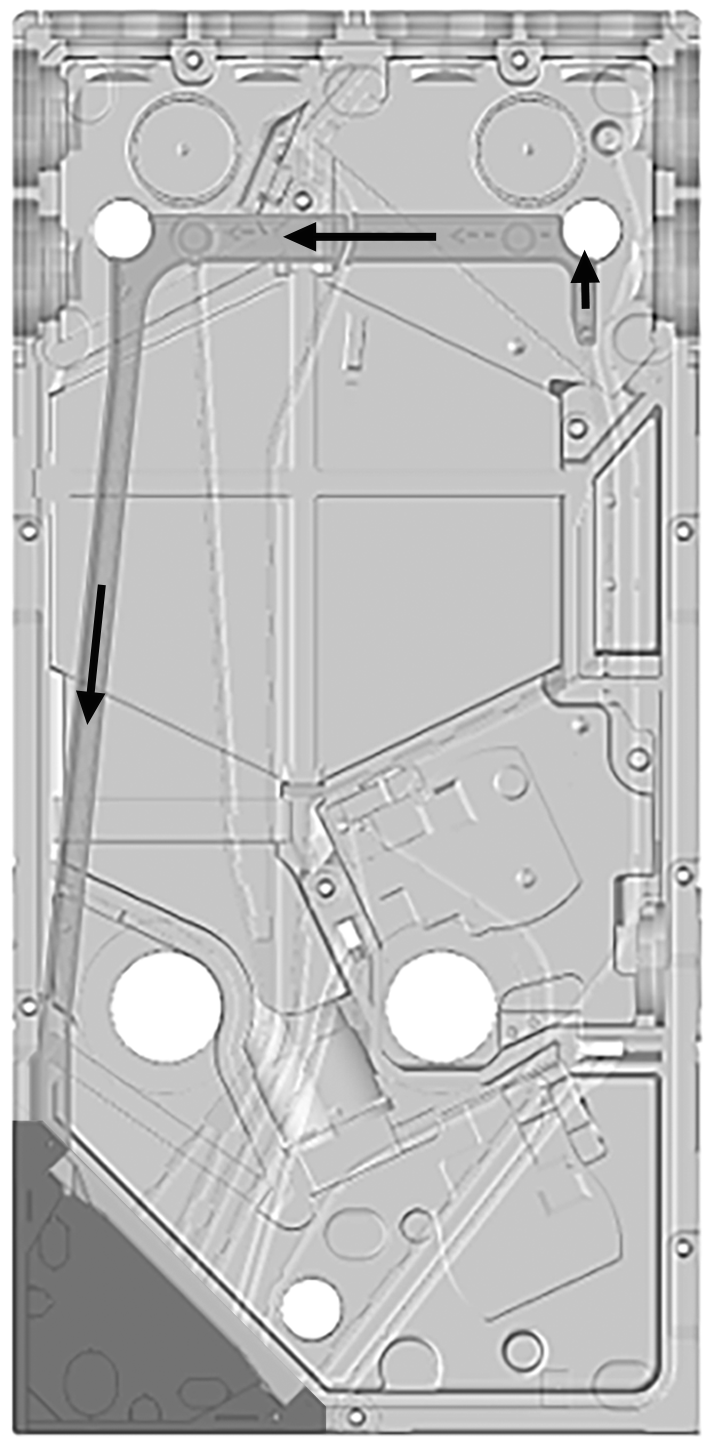

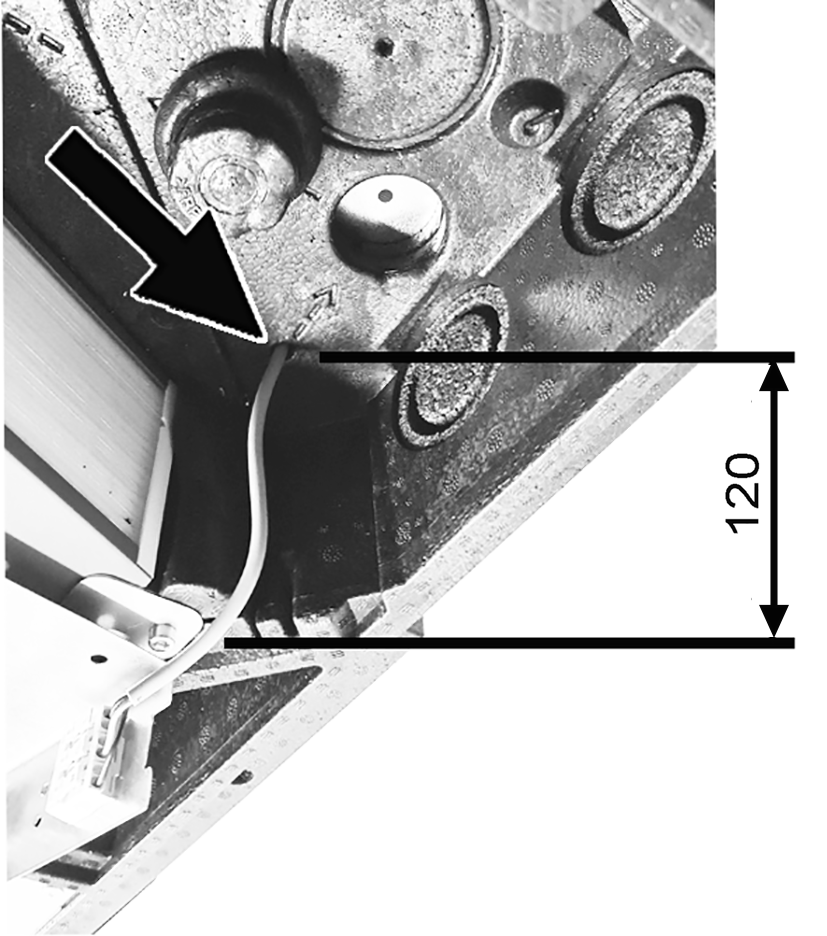

- Make a 90° elbow in the connecting cable and thread the cable from pos. ③ into the electronics compartment. Observe arrows in EPP housing.

- Connect the connection cables to the spring terminal X5 of the main circuit board → Wiring diagram.

- Insert both EPP sealing plugs into the EPP housing.

- Install the cover, electronics compartment and front cover.

- Attach housing cover.

- Perform function test via the switching test function

. Using the commissioning software, set the Supply air heat register parameter to on in the main menu Settings/Switching test. After a short time the supply air fan starts. When functioning correctly, heated air flows out of the supply air opening. Set Supply air heat register parameter to off.

. Using the commissioning software, set the Supply air heat register parameter to on in the main menu Settings/Switching test. After a short time the supply air fan starts. When functioning correctly, heated air flows out of the supply air opening. Set Supply air heat register parameter to off.

Guide the connecting cable, in 3 steps, into the electronics compartment. For this, use a pulling aid (wire/wire cable), otherwise the installation is difficult due to 90° bends. Ensure tight cable routing. For cable routing → Figure.

Guide the connecting cable, in 3 steps, into the electronics compartment. For this, use a pulling aid (wire/wire cable), otherwise the installation is difficult due to 90° bends. Ensure tight cable routing. For cable routing → Figure.