Installing WW 90 wall sleeves with WS 75 H MP mounting plate

As an alternative to the WS 75 RSAP, you can also use the WS 75 H MP mounting plate for WS 75 surface mounting with wall-side outgoing air/outside air connections. This is particularly suitable for construction projects with several WS 75 H units.

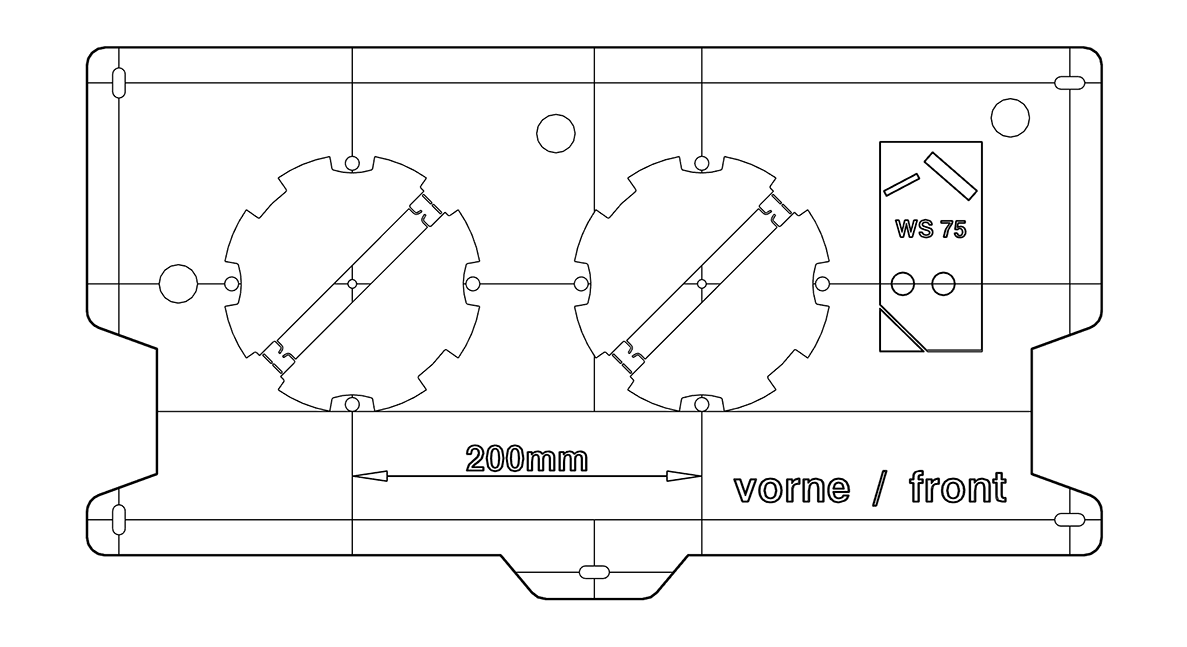

The mounting plate can be used to precisely position the core drill holes and attach them to the exterior wall as described in steps 9 and 10.

Ensure a slope of 1 to 2 % to the exterior wall for the WW 90 wall sleeves. Foam these tightly all round with mounting foam (non-pressing) in masonry. The mounting plate can then be removed and used for the next installation of the WW 90 wall sleeves or optionally remain mounted.

- Break out the two sheet metal cross struts and angle the two sheet metal stops 90° towards the inside of the room → Chapter 10.1.

- Align the mounting plate with the mounting position of the exterior wall and screw it to the wall. ATTENTION: Provide sufficient space for the installation of the RSAP metal shell sheet.

- Mark the two core drill holes, remove the mounting plate and drill the two DN 160 mm core holes.

- Insert the WW 90 wall sleeves as described in steps 9 and 10 in the previous chapter, fill with mounting foam and allow to harden, follow the installation instructions!

- During the shell construction phase, protect the WW 90 wall sleeves from soiling with the protective covers provided.

When installing the WS 75 Powerbox H final installation unit, note the following: The Powerbox H is screwed to the wall using the 4 mounting brackets on the side. Ensure exact positioning of the core drill holes and tightness of the connections. To use the WS 75 APA, the WS 75 RSAP shell installation kit is still required.

When installing the WS 75 Powerbox H final installation unit, note the following: The Powerbox H is screwed to the wall using the 4 mounting brackets on the side. Ensure exact positioning of the core drill holes and tightness of the connections. To use the WS 75 APA, the WS 75 RSAP shell installation kit is still required.