Preparations for wall installation

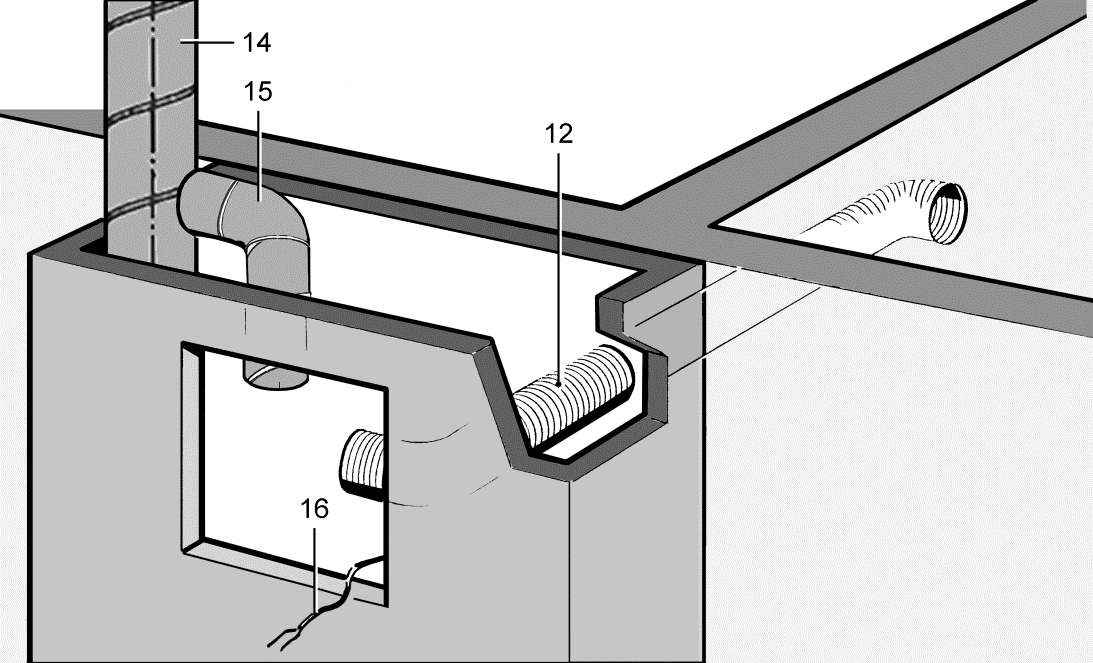

12 | Suction duct for second room connection on ER GH: AFR 75 / AFR 80 flexible aluminium duct |

14 | Main duct: Steel folded spiral-seams duct |

15 | Connection duct on ER GH: AFR 75 / AFR 80 flexible aluminium duct permitted inside the shaft |

16 | Power cable |

Installation information

- Observe approval: Certificates of approval and Requirements in line with approval.

- Always use correct duct material for the housing.

- For fire protection systems, the gap remaining between the connection duct and brickwork/wall boards/wall/ceiling must be fully sealed with non-flammable materials that are resistant to deformation (e.g. concrete, cement mortar, fire protection filler).

Damage to unit, malfunctioning in the event of corrosion damage from mortar.

Damage to unit, malfunctioning in the event of corrosion damage from mortar.

- Wrap ventilation ducts, connected to the unit, with a suitable adhesive tape to protect against corrosion inside the brickwork, e.g. using cold-shrink tape.

Preparing the shaft

- Produce opening in shaft or alternatively produce a wall facing. Ensure a suitable, flat surface for the housing so that the fan insert can be safely inserted in the housing later on.

- For a second room connection, produce an opening in the wall or shaft for the suction duct. Note permissible housing installation positions.

- Correctly attach main duct inside the shaft.

- For fire protection systems, use ceiling compound. To do this, encase the ceiling and pour in the material from above.

- Connect connection duct, suitable for the housing, to the main duct and seal for ventilation.

- Cut connection duct to length, note a maximum duct length of 6 m.

- Lay suction duct and seal gap remaining correctly as described in previous mounting instructions.

- Lay power cable in shaft and allow to protrude by around 30 cm above the shaft opening.

- Lay power cable: Electrically connecting the unit.