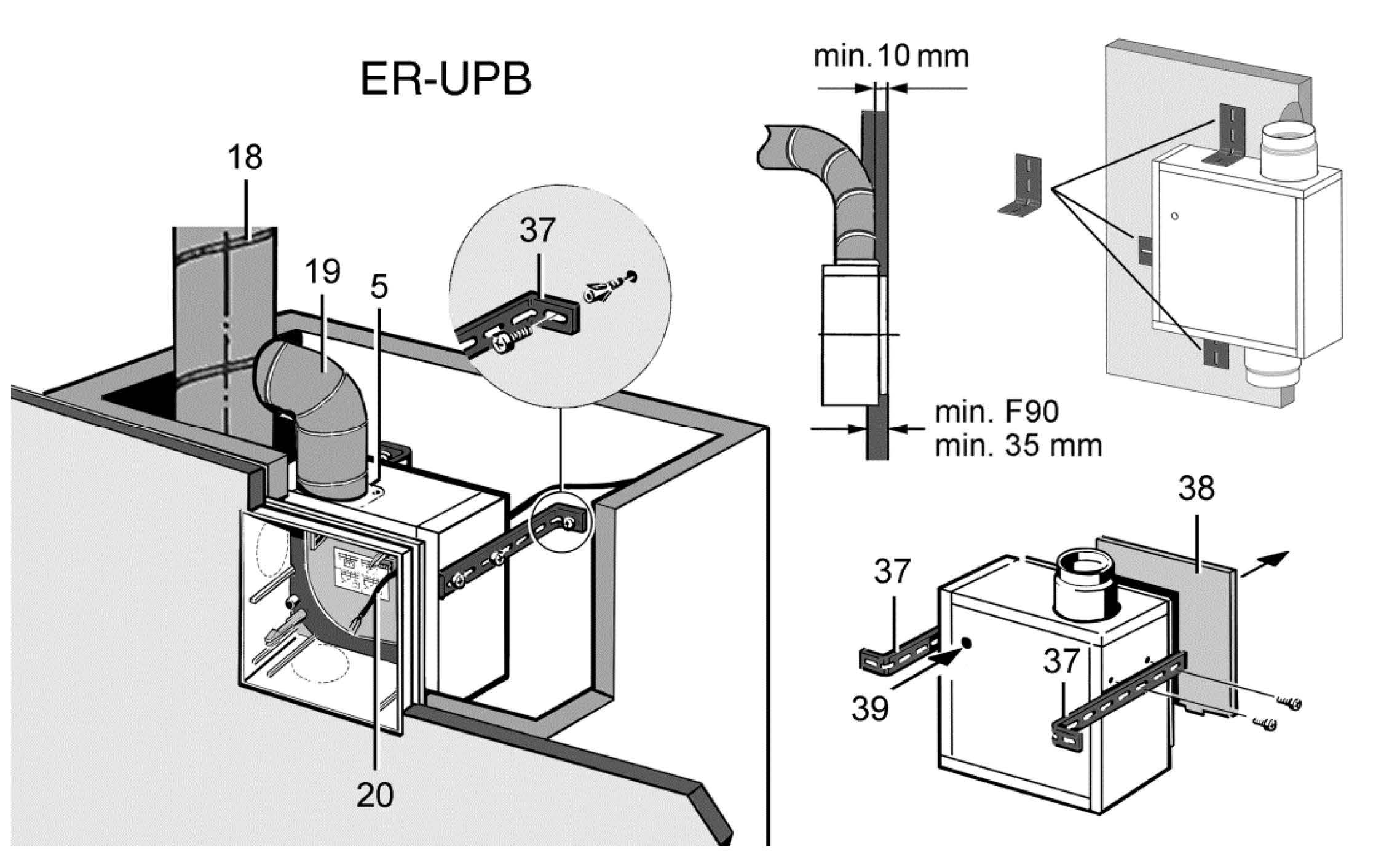

ER-UP/B installation, single room

5 | Metal exhaust socket with shut-off shutter |

18 | Main duct, steel folded spiral-seams duct |

19 | Connection duct, flexible aluminium duct AFR DN75/80 |

20 | Power cable |

37 | UPM 60/100 mounting support |

38 | Plaster protective cover |

39 | Cable grommet |

- Remove the plaster protective cover from the housing.

The unit will be damaged and function impaired if the fixing screws used are incorrect/too long.

The unit will be damaged and function impaired if the fixing screws used are incorrect/too long.Fixing screws may not penetrate into the housing.

- Use the screws provided (UPM 60/100 mounting support).

- For suspended ceilings, cut mounting support to the required length, bend it into shape and fix it to the ER-UPD housing with the supplied screws.

- Mark fixing holes for mounting support on ceiling, drill dowel holes and insert steel dowels.

Danger of short-circuits and damage to the unit.

Danger of short-circuits and damage to the unit.If the cable grommet is not installed correctly, water may penetrate the housing. The degree of protection can no longer be guaranteed.

- Drive through cable grommet so that it can seal the cable sheathing all the way round (circular, no slots).

- Guide power cable from rear of housing through cable grommet into housing.

- Move housing into desired position and secure to ceiling with both mounting supports.

Fire may spread if connection duct is incorrectly installed.

Fire may spread if connection duct is incorrectly installed.- Only use permitted duct material (Requirements in line with approval).

- Correctly attach connection duct to exhaust socket.

- Slide connection duct to stop above exhaust socket. Secure connection duct and exhaust socket with 3 steel blind rivets. Then seal well for ventilation, e.g. with cold-shrink tape.

- Produce electrical connection.

- Insert the plaster protective cover in the housing.

- Plaster in housing flush with front edge, note tile thickness if necessary: Important information about plastering.