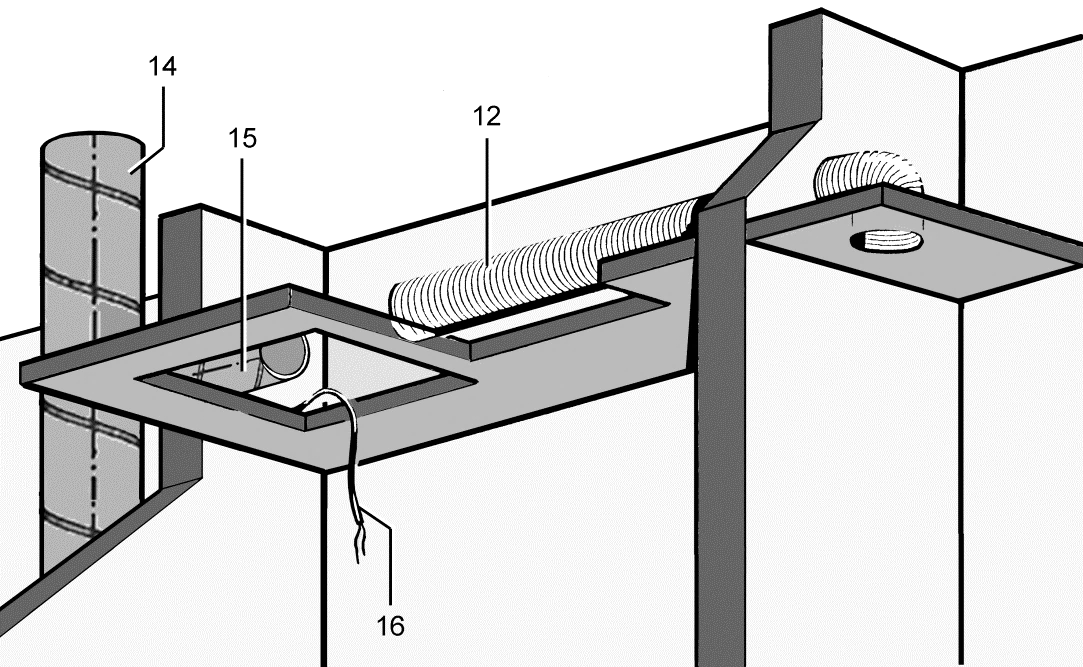

Ceiling installation preparations

12 | Suction duct for second room connection on ER GH: AFR 75 / AFR 80 flexible aluminium duct |

14 | Main duct: Steel folded spiral-seams duct |

15 | Connection duct on ER GH: AFR 75 / AFR 80 flexible aluminium duct |

16 | Power cable |

: Preparations for wall installation.

Preparing the shaft and suspended ceiling

- Make an opening in the suspended ceiling.

- Make an opening in the shaft for DN 75 or DN 80 connection duct.

- For a second room connection, produce the opening in the wall or shaft for the suction duct. Observe installation positions for the second room connection.

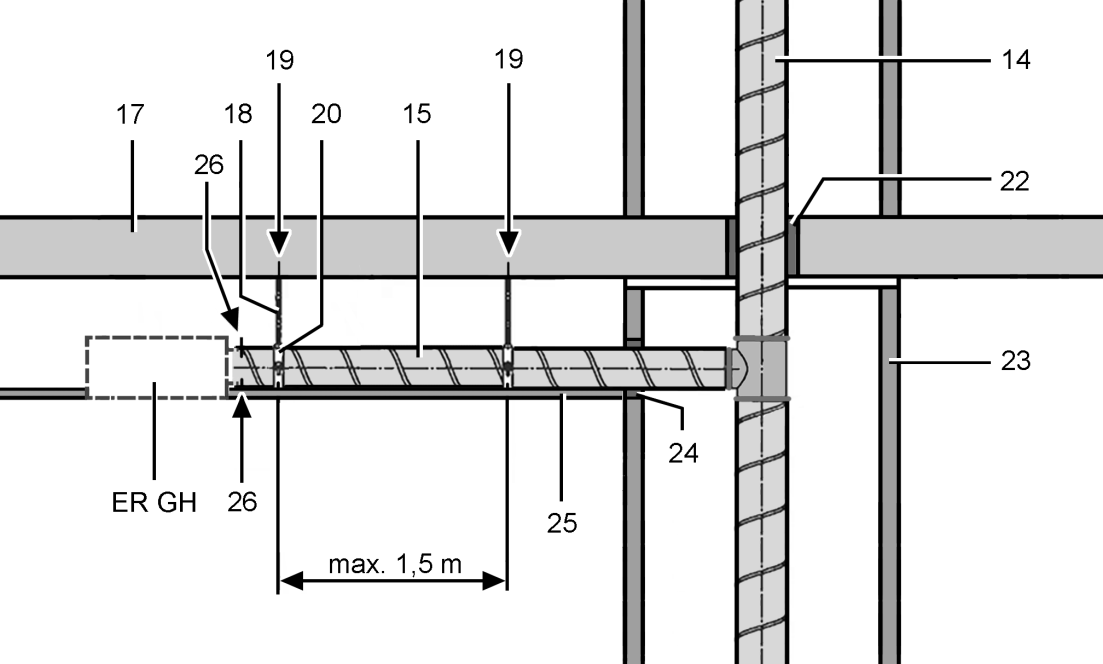

14 | Main duct (steel folded spiral-seams duct) |

15 | ER GH connection duct: Flexible aluminium duct |

17 | Floor ceiling |

18 | Steel threaded rod / stair bolt |

19 | Duct attachment |

20 | Duct clamp / clamping band |

22 | Ceiling compound |

23 | Shaft wall |

24 | Wall/wall board seal |

25 | Suspended ceiling |

26 | Steel screws or steel blind rivets (3 of each) |

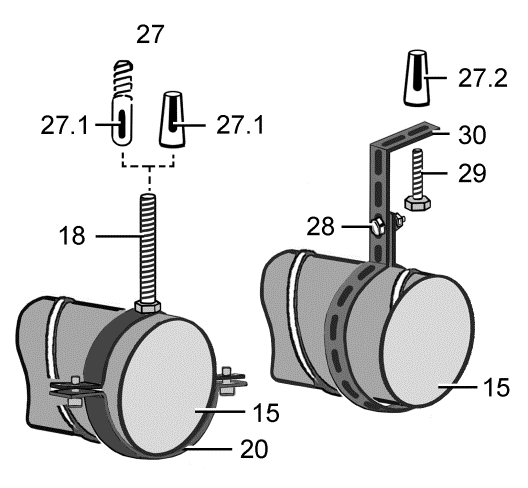

27 | Dowel |

27.1 | Plastic dowel or anchor bolt |

27.2 | Metal expansion dowel |

28 | Retaining bolt with nut |

29 | Retaining bolt |

30 | Steel clamping band |

: Preparations for wall installation.

Duct attachment with duct clamp, alternatively duct attachment with clamping band

.

- Correctly attach main ventilation duct inside the shaft.

- For fire protection systems, use ceiling compound. To do this, encase the ceiling and pour in the material from above.

- Fit duct attachments to the ceiling. Only use permitted mounting material.

Risk of incorrect installation if non-permitted mounting material is used.

Risk of incorrect installation if non-permitted mounting material is used.- Only secure connection duct to ceiling with permitted mounting material (duct clamp or clamping band).

- Connect permitted connection duct to main duct and seal for ventilation, for example with cold-shrink tape.

- Apply wall/board compound. Seal gap between brickwork and folded spiral-seams duct. The gap remaining must be fully sealed with non-flammable materials that are resistant to deformation. For example, use concrete or cement mortar or for wall boards, use fire protection filler.

- Fit suspended ceiling. Use housings to ensure a suitable, flat surface so that the fan insert can be safely inserted in the housing later on.

- Lay power cable: Electrically connecting the unit.

Be sure to note the approval and installation information

Be sure to note the approval and installation information